In November 2005, the ALSTOM Power Conversion division became Converteam. As a technology leader in the field of electrical energy conversion, with more than 3300 employees and an active presence in more than 80 countries, the new company became one of the key players in the industry and marine markets. In March 2011, GE Power acquired the majority stake of Converteam and integrates its operations in his GE Power Conversion division.

The broad product line ranges from simple off-the-shelf low voltage drives at only 0.25kW, up to the largest available engineered drives of over 100MW. And, because the company incorporates its own drives into other manufactured equipment and systems, years of user experience have guided the development of every one.

For systems integrators, who need high-quality drive components to build into their own drive solutions, CONVERTEAM range of drives also includes low voltage drive modules, inverters, and rectifiers up to 3.6MW. From simple to complex requirements from 200V fans or pump drives of a few kilowatts, to large conveyor drives with sinusoidal current return to the mains supply, to a medium voltage drive up to 10kV output without any transformer- CONVERTEAM drive range provides the solution. And for special drive applications, customised products and solutions are available on request.

Nowadays, our scope of supply is limited mainly to spare parts for the installed base, including original and OEM parts manufactured under ALSTOM, Converteam and/or GE licence.

Standard Equipment

- DC drives from 7.5kW to 25MW (customised drives above 750kW)

- AC drives for low voltage induction motors from 0.25kVA to 5MVA

- AC drives for medium voltage induction motors from 300kVA to 25MVA

- AC drives for synchronous or wound rotor motors from 0.25kW to 100MVA

- Semipol Static Excitation Equipment for field current, power up to 1000 MW

- Cement mills, crushers

- Compressors

- Pumping systems

- Conveyors

- Cranes

- Extruders, mixers

- Fans

- Machine tools

- Marine propulsion

- Metal rolling mills

- Mine hoists

- Paper making

- Presses

- Process lines

- Rolling roads

- Test benches

- Wind tunnels

- Wind turbines

- Power plants equipped with induction or synchronous machines

AC Drives - ALSPA Series MVxxx and MV Delta

ALSPA drive range drives solutions

Drives catalogue

ALSPA Drives and Soft Starters

ALSPA MV3000 and MV Delta

ALSPA MV3000 is a range of compact variable speed AC drives covering the majority of industrial applications from general purpose machinery to high performance process lines. Ranging from 22kW to 3.6MW, ALSPA MV3000 offers a choice of control modes including:

Building on the success of ALSPA GD3000E and ALSPA MD2000, the ALSPA MV3000 combines the functions of both into

one package and adds further impressive features making it the choice for all variable speed drive users - no matter

what the applications.

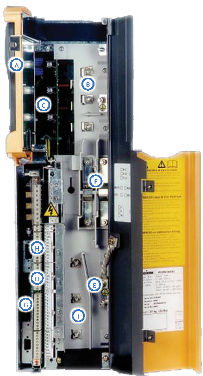

Up to 315kW, the ALSPA MV3000 is in chassis unit format using the MicroCubicle™ concept.

MicroCubicle™ means:

The Drive Data Manager™ redefines the keypad concept with menu navigation, on-line help, quick start and instrumentation facilities all wrapped up in an ergonomic design with a large, easy to read display

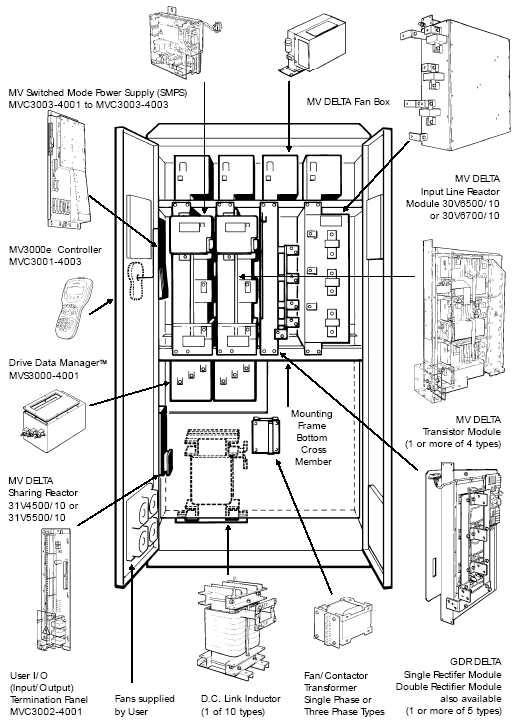

From 315kW to 3,600kW, ALSPA MV3000 is available in DELTA format. DELTA format drives can be supplied either as a kit of parts ready for building into a cubicle or as a completely built and tested package ready for site installation. DELTA format drives are modular in construction. They use the same control system, Drive Data Manager™ as the ALSPA MV3000 chassis units. These are combined with up to 6 DELTA inverter modules running in parallel.DELTA format MV3000 is available air cooled from 300kW to 1,800kW or liquid cooled from 600kW to 3,600kW.

ALSPA MV3000 - Compact Drives in stock to replace installed equipment

Air Cooled ALSPA MV3000 Delta - Spare parts in stock to support the installed base

Air cooled ALSPA MV3000 Delta - Spare partes and replacement modules in stock to support or update the installed base

Liquid cooled ALSPA MV3000 Delta - Spare partes and replacement modules in stock to support or update the installed base

Data Sheet

Buyers Guide

Active energy management

Static frequency converter - IGBT - with constant DC-link voltage for applications up to 5.5 MW

MD2000 are fully digital frequency converters with constant DC-link voltage for continuous speed variation of AC - motors.

Vector control as standard feature - even without encoder feedback - ensures maximum performance; further control modes selectable.

Standard MD2000 can be expanded using Hard- and Software options.

The handling is identical throughout the range and convinces by simplicity and maximum flexibility. The MD2000 can be programmed on site with

the optional keypad. Also as an option, the extremely powerful visualisation and operating software is avalable.

MD2000 offers significant advantages to the user:

- Full range from 15 - 4500 kW with IGBT´s

- Output frequency range:0 ... 300 Hz

- High Overload capability available

- No - load, short circuit and earth fault proof

- Simple handling with clear text display

- Vector control with and without encoder

- Automatic restart function after mains failure

- Powerful software functions "Support and Capture" as standard

- Kinetic support after mains failure with excellent efficiency

- Basic Drive Modules (BDMs) up to 365 KVA, 3AC Main connection up to690 VAC.

IP20, BDM with diode bridge, IGBT power stack, DC-link capacitors, control electronic, fan, pre-charge unit and built-in contactor in the DC-link.

Mains choke, relay outputs, keypad, switching equipments and fuses are not included. - Basic Drive Modules (BDMs) up to 365 KVA, DC Main connection up to930 VDC.

IP20, IGBT power stack, DC-link capacitors, control electronic, fan, pre-charge unit and built-in contactor in the DC-link.

Relay outputs, keypad, switching equipments and fuses are not included. - Chassis Units Cubicle Mounted up to 365 KVA, 3AC Main connection up to690 VAC.

IP21, MD2000 BDM (see above), Load fuse isolator with semiconductor fuses and lockable operating handle Mains choke uk=2% for 400V, uk=4% for 500V and 690V, terminal board, Rittal rack, colour RAL 7032, Rittal key, keypad cubicle door mounted, 60V relay outputs.

Main characteristics

- Reduction of capital investment and operating costs thanks to latest IGBT technology.

- Optimum pulse pattern allow high motor utilisation and along with its overload capability MD2000 generates a direct saving in investment costs

- Modular hardware and software matches easily with any technical requirement

- Design of decentralised automation systems using fi eld bus connection

- Easy operation through the control panel and easy commissioning with PC visualisation software PCs

- Comprehensive safety and monitoring facilities

- Four-quadrant applications

- With optional brake chopper

- Energy regeneration with MD2000 AEM

- Sinusoidal mains current control

- High dynamic performance

- Variable mains power factor cos φ ± 1 ... ± 0,8

- Construction of DC system bus with ready-to-connect MD2000 inverters

- Field bus coupler for integration into

- automation systems

- CANopen (on board)

- Profi bus DP/FMS

- Interbus S

- Modbus Plus

- Bitbus

- SNET

- World FIP (F8000)

- The link voltage is maintained by the “regenerative ride-through“ facility in the event of mains voltage drops. If mains power should fail, the drive decelerates under control and is restarted automatically if required.

Braking energy optimally exploited

In many drive tasks, several induction motors work together: partly driving motor, partly regenerative braking (e.g.

on gearbox test benches, coiler drives in rolling mills or on paper machines etc.).

A common DC busbar for all inverter units allows utilisation of the braking energy – by the shortest distance without passing mains.

Therefore the incoming supply of the DC busbar is to transmit a part of the entire power only.

ALSPA MD2000 - Accesories and spare parts for supporting the installed base

The LV7000 family comprises compact and high performance drives. The key design feature is the software and hardware modularity. Two types of control are available – the standard sensor-less vector control and the closed loop flux vector control for more demanding applications. LV7000-1 is a space-saving compact drive whereas the LV7000-2 and 3 is a high-performance drive combined with powerful support for various software applications. In addition to the standard I/O in the basic drive, there is room for option cards with more I/O, fieldbus cards or additional application specific hardware. The option cards can be used in all three drive types: one option card in the LV7000-1 to expand the basic drive, and up to five option cards in the LV7000-2 and 3 to create the necessary configuration for your application.

The drives are easy to program and use via the keypad. The keypad can easily be removed for hand held use or door mounting. The LV7000-1 has a detachable, seven-segment LCD keypad without memory capabilities. It is used to communicate with the drive, set parameters and for monitoring. The LV7000-2 and 3 have a detachable, alpha-numeric keypad with built-in memory. In addition it can be used to copy parameters between different drives and storage of the active parameters for future use.

All Converteam LV7000-2 and LV7000-3 drives are delivered with the All in One application package,

a selection of pre-installed applications. An application is a predefined set of parameters and functions, designed for a specific purpose.

When you choose the application that corresponds to your requirements, the drive will be easy to set up. All required parameters are available, but the

parameters which are not needed in the specific application, will be hidden. For each application there is a start-up wizard that will guide you through the

start-up process and parameter settings. The drive is also capable of identifying motor parameters, further easing the start-up.

All applications support fieldbuses. The application that best fits your needs can be chosen from the following:

- Basic application

- Standard application

- Local/remote application

- Multi-step speed control application

- PID control application

- Multi-purpose control application

- Pump and fan control with autochange

- Customized applications

LV7000-1

The compact size and flexible installation options make the LV7000-1 suitable for installations where space is at a premium. The small MF2 and MF3 frames can be mounted using a DIN rail either at the back or at the side of the drive; the larger MF4-MF6 frames are wall mounted.The LV7000-1 includes an easy-to-use and flexible multi-control application. The need for parameter adjustments is kept to a minimum, thanks to well-defined default settings. All I/Os can be programmed. The versatile features include full motor protection, flying start function, sleep function and a PID controller, with the possibility to control 3+1 pumps (PFC). The bookshelf design, the enclosure options and EMC classes offer an optimal solution for all operating environments.

Features:- Steady state speed error less than 1%

- Low torque ripple

- High immunity to resonance vibrations

- Starting torque > 200% depending on motor and drive sizing

- Suitable for multi-motor applications

- Single Phase models: 208-240VCA / 0.25-1.5kW

- 3 Phase models: 380-500VCA / 0.37-30kW

Technical Data LV7000 Family

LV7000-2

The LV7000-2 is designed to be a standard, easytouse drive with a wide application area. It is based on an advanced sensorless vector control concept, which gives a very good motor control under all circumstances. An automatic torque maximizer feature is available, ensuring that all loads can be started reliably. It also includes an automatic energy saving feature, which optimizes the motor flux as a function of motor load and speed. The basic drive operation is also suitable for multi-motor applications.

Features:- Steady state speed error less than 1%

- Low torque ripple

- High immunity to resonance vibrations

- Starting torque > 200% depending on motor and drive sizing

- Suitable for multi-motor applications

- High-speed applications (up to 7200 Hz) possible

- mains voltage from 208 VAC to 690 VAC, power up to 2 MW

Technical Data LV7000 Family

LV7000-3

The LV7000-3 is used in all cases where a very high precision of speed and torque under all circumstances are required. Equipped with high processing power, the LV7000-3 can use information from an encoder or a resolver in order to provide very precise motor control. Sensorless vector and normal U/f control are also supported. Typical applications requiring high performance are:

- master-slave drives

- positioning applications

- winder tension control

- and synchronization

- Speed error less than 0.01%, depending on the encoder

- Incremental or absolute encoder support

- Encoder voltages of 5 V (RS422), 15 V or 24 V, depending on the option card

- Full torque control at all speeds, including zero

- Torque accuracy less than 2%; less than 5% down to zero speed

- Starting torque > 200%, depending on motor and drive sizing

- Full capability for master/slave configurations

- Integrated data logger for system analysis

- Fast multiple drive monitoring with PC

- High-speed bus (12 Mbit/s) for fast inter-drive communication

- High-speed applications possible

- same ranges as LV7000-2 model

Technical Data LV7000 Family

ALSPA MV500

Obsolete, no spare parts availableReplaced with the LV7000 Drives family

The ALSPA MV500 range of low power drives brings reductions in both cost and complexity. No drives knowledge is required to install and use this drive in most applications. The drive offers ease of operation with only 10 parameter settings required for most applications.

Features:- power from 0.25 KW to 15 KW

- nominal output current from 1.5 A to 30.5 A

- one control card with 2 processors

- a 2-wire RS485 serial link networking options: Profibus, Modbus + Interbus S, DeviceNet, CAN digital or analog I/O

- single or three-phase power supply: 200-240 V or 380-480V

MV500 User Guide

MV500 Advanced user guide

ALSPA MV1000

Obsolete, no spare parts available.Replaced with the LV7000 Drives family

Intelligent drive technology from 0.75 kW up to 45 kW. ALSPA MV1000 complements our well-known ALSPA MD2000

series in the lower power range while using the same software and user-interface.

The versatile hardware and software in the MV1000 allows special solutions, making drive technology more

flexible. The series is equipped with many integral freely configurable facilities. Custom application software

is created by our engineers using the LogiCAD project design tool.

The drive is an inverter suitable for any drive configuration in single or multiple motor systems.

Four-quadrant operation is possible with DC-braking including mains generation.

MV1000 Operating Manual

MV1000 Quick start programming guide

ALSPA DC Drives

ALSPA VNTC and WNTC

Obsolete, no spare part available. Please, ask for replacement.

V/WNTC is the latest family of advanced, micro-processor controlled DC variable speed drives.

The range of output current is from 25 A to 1850 A. All sizes share control, monitoring, protection and serial

communications. All are available in either 'single-quadrant' or 'four-quadrant' configuration.

Single-quadrant drives provide forward run operation only. Four-quadrant drives are fully-reversible.

Both types offer comprehensive control of motor speed and/or torque.

Data-Sheet WNTC/VNTC

SEMIPOL Static Excitation Equipment

Coupled with a Static Frequency Converter, Power Conversion’s static excitation equipment provides performing coping with grid power variation, with one single interface to the power plant control. The static excitation equipment can be tailored to many types and sizes of power plants. In addition, pump turbines are usually equipped with induction or synchronous machines.

Features & Benefits:- Performance: Field current from 20 MW to 1000 MW

- Reliability: Redundancy fans, Thyristor bridge and control

- Safety: Integrated power system stabilizer and control limiters for field and static current

- Cost savings: No diagnostics and maintenance needed

- Simple use: Customer interface for simple operation.

Spare parts:

MV7000

MV7000 drives cover medium and high power ranges up to 81 MW with motor voltages from 3.3 to 10 kV and higher voltages on request.

The drives are water-cooled Pulse Width Modulation (PWM) voltage source inverters. They can feed both induction

and synchronous machines with high performance vector control, across all speed ranges.

The modular MV7000 drive features options such as regenerative front ends, dynamic braking choppers and connection to a common DC bus, thus

ensuring that the drive can be configured to suit virtually all applications.

MV7000 drives feature, as standard, a 12-pulse or 24-pulse diode front end converter, fed by a 2 or 4 phase-shifted

secondary winding transformer. The harmonics injected into the network are very low.

The drive complies with international standards for voltage and current harmonic distortion, without additional

harmonic filters or VAR compensation equipment. The drive continues to operate in the event of voltage dips

without tripping (fault ride through).

- Power quality: low harmonics and high power factor minimizing effect on supply network

- Quality output: connection to new and existing standard motors without derating

- Performance with high efficiency up to 99%

- Reliability with press-pack IEGT technology, fuseless protection and low component count

- Power density: up to 1.1 MVA/m3 for the complete drive

- Low operating costs

- Ease of maintenance, no rear access required

Available Spare parts: Please ask

AEG DrivesObsolete, no spare parts available - Please, ask for replacements.

Microverter / Microverter D

Analog Voltage source inverter.

Replacement parts and service are not available.

Documents are available only as paper copies. Please contact us for more information.

A small DC converter with a rating between 0.68kW and 4.5kW

Replacement parts and service are not available.

Documents are available only as paper copies. Please contact us for more information.

Analog and digital DC converter rated from 18kW to 660kW

Replacement parts and service are not available.

Documents are available only as paper copies. Please contact us for more information.

Analog DC converter

Replacement parts and service are not available.

Cubicalised DC converter with ratings from 388kW to 3120kW

Replacement parts and service are not available.

Documents are available only as paper copies. Please contact us for more information.

Obsolete, spare parts only available for supporting of installed base

ALSPA 80-35

With small, medium and high powered CPUs and a full range of network options, the ALSPA C80-35 creates a compact, easy to use control system that can be matched closely to the needs of the application.

Features:- 128 to 4096 I/O

- 6kB to 256 kB memory

- Single and dual redundant configurations

- Local, distributed or remote I/Operating

- Ladder diagram, SFC, Function Block, and ''C'' Languages

ALSPA C80-35 Data-Sheet

ALSPA C80-35 Programming Manual

Remote I/O CE80-20

In many control systems, the controlled plant is spread out over a wide area. The ALSPA CE80-20 distributed I/O system allows the input/output units to be located with the controlled plant, saving on cabling and physical space.

Features:- DIN rail mounted

- Integral terminal block

- Hot swap option

- ALSPA F8000, ALSPA N80 and Profibus-DP networking

Bus WorldFIP CE80-20

ALSPA CE80-35

For applications requiring a large number of I/O in a single location, the ALSPA CE80-35 provides a compace, space-saving solution.

Features- High density I/O modules

- Up to 320 I/O on a single base plate

- ALSPA F8000 networking

- Time stamping features (10 mS)